N. J. Engineers

Our Products

ELBOW

BENDS

RETURN ELBOW

TEE

COUPLING

CONC&ECCN.REDUCER

Our Organization

QUALITY ASSURANCE PROGRAMME

The scope of this Quality Assurance Programmed is to manufacture pipe fittings viz; Butt welded, Socket welded, Threaded and flanges as per various national & international material and dimensional standards.

The materials used for manufacture of these fittings are Carbon Steel, Alloy Steel, and Stainless steel for moderate temperature, high temperature & Low temperature services. Quality Assurance Plan comprises of controls & systems to be followed during manufacture of pipe fittings and other products so that an audit mechanism is introduced during manufacture itself, finally meeting the requirements ofspecification.

A separate Quality Control department functioning under the control of Quality Control Manager maintains all the records. Engineers and inspectors check the material at various stages of manufacture.

Before actual purchase of raw material, Quality Control Inspector checks all the material visually for surface defects. A dimension check is carried out to see if the

dimensions are as per the required code. The manufacture’s test certificate is scrutinized and identified with the material. A Chemical check test is carried out on one sample from the lot to verify the authenticity of Test Certificate, or when proper test certificate or marking is not available. In case the material is acceptable, a identification number is assigned and punched on each lot offittings / forgings.

Prior to cutting the material which may be in the form of Pipes, plates, etc, the identification number is transferred on every piece which may be cut from the parent material. After forging/forming each piece, the same is re-stamped if the identification number is notvisible.

Heat treatment is done on all the material as per the requirement of applicable specifications. The heat treatment furnaces are fitted with probes (thermocouples)

& a temperature recorder for getting an accurate record of time temperature graph for analysis. The recorder is re-calibrated by E.Q.D.C. BARODA every year. A complete record of Time-Temperature Graph, Heat Number Calibration Certificates, etc, ismaintained.

Looking for a quality and affordable services for your next project?

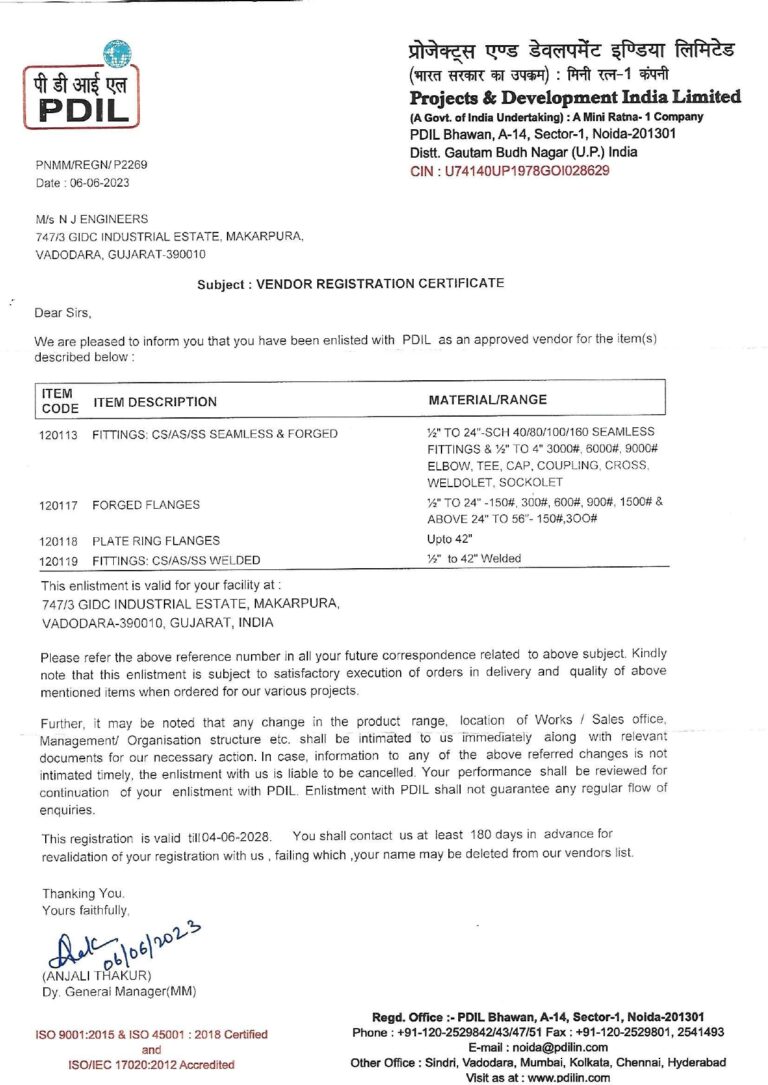

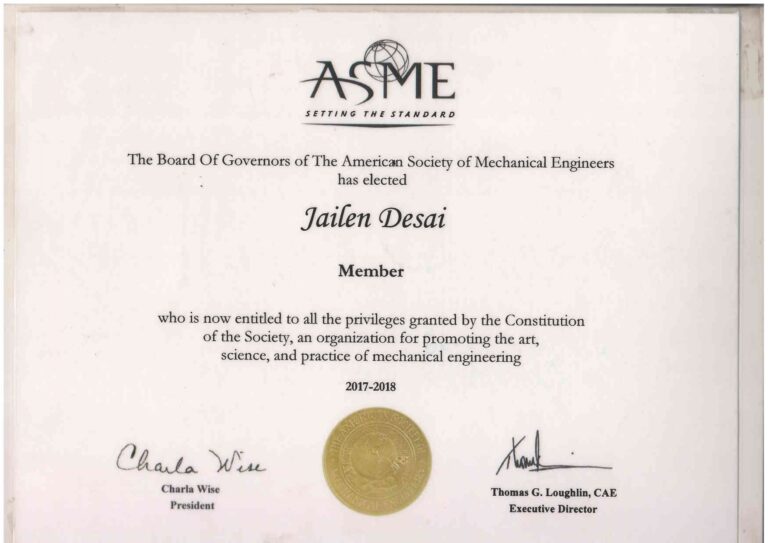

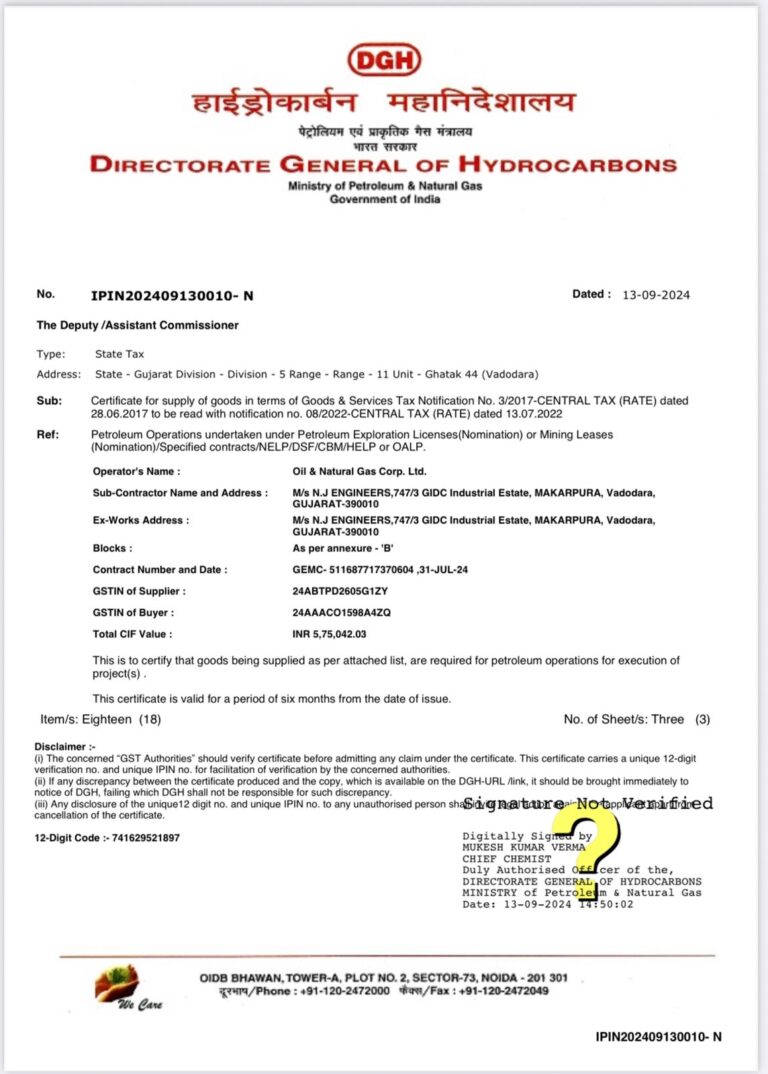

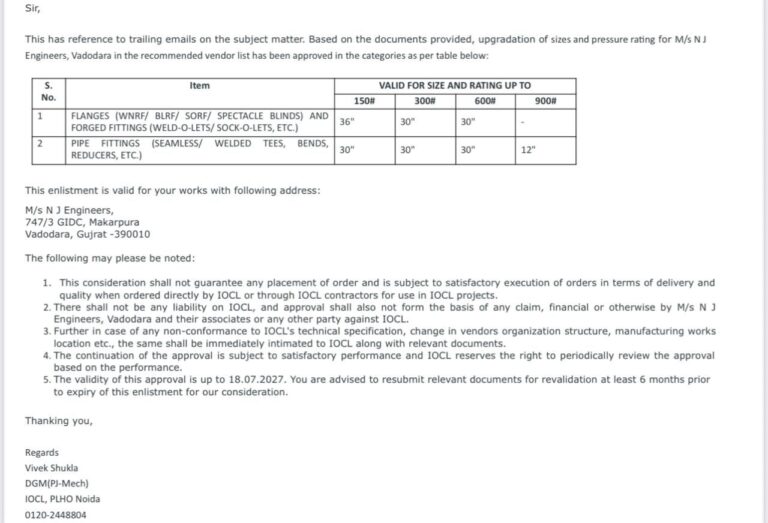

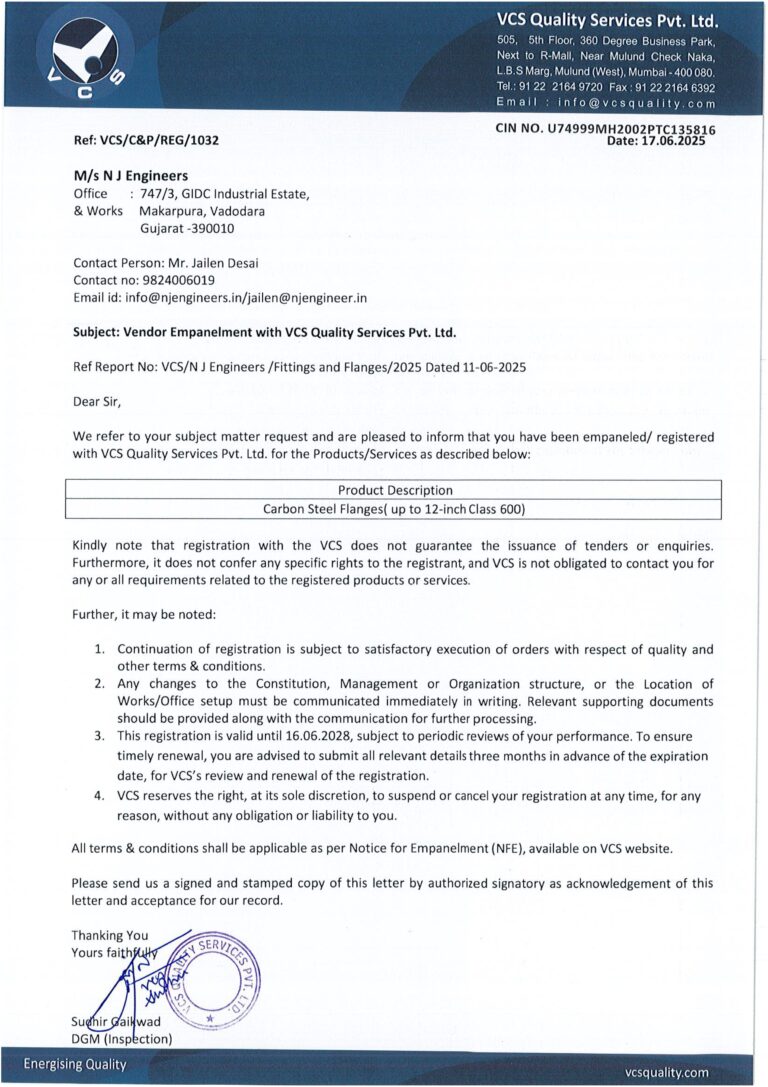

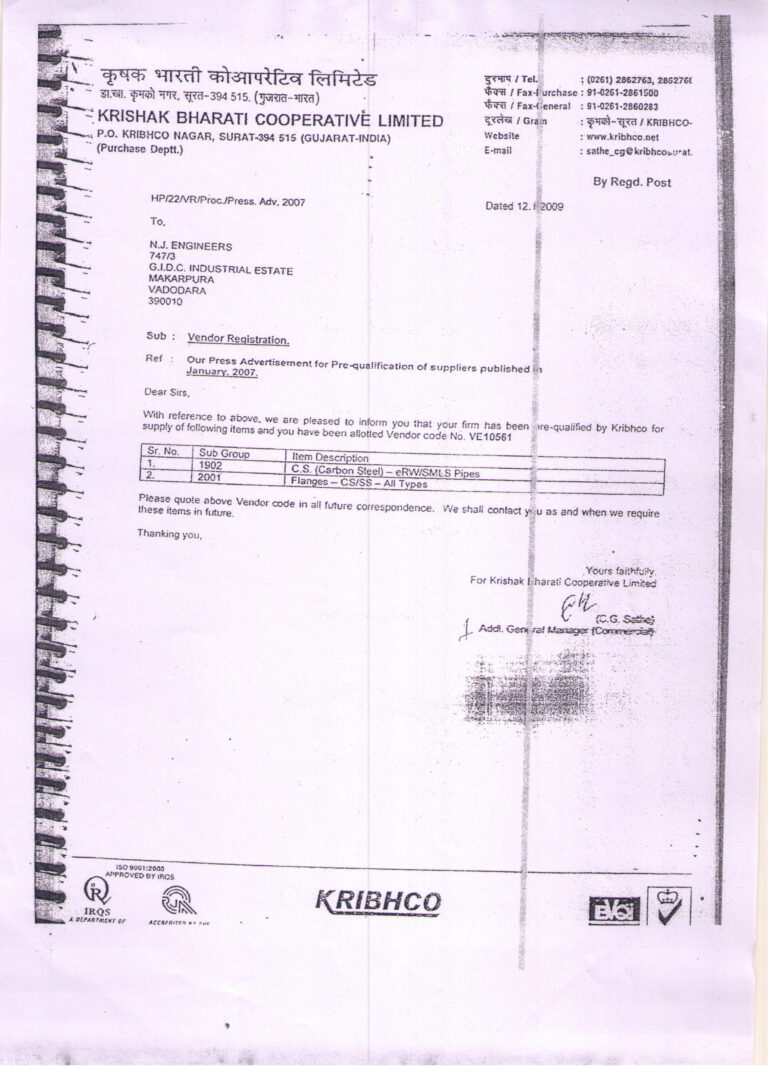

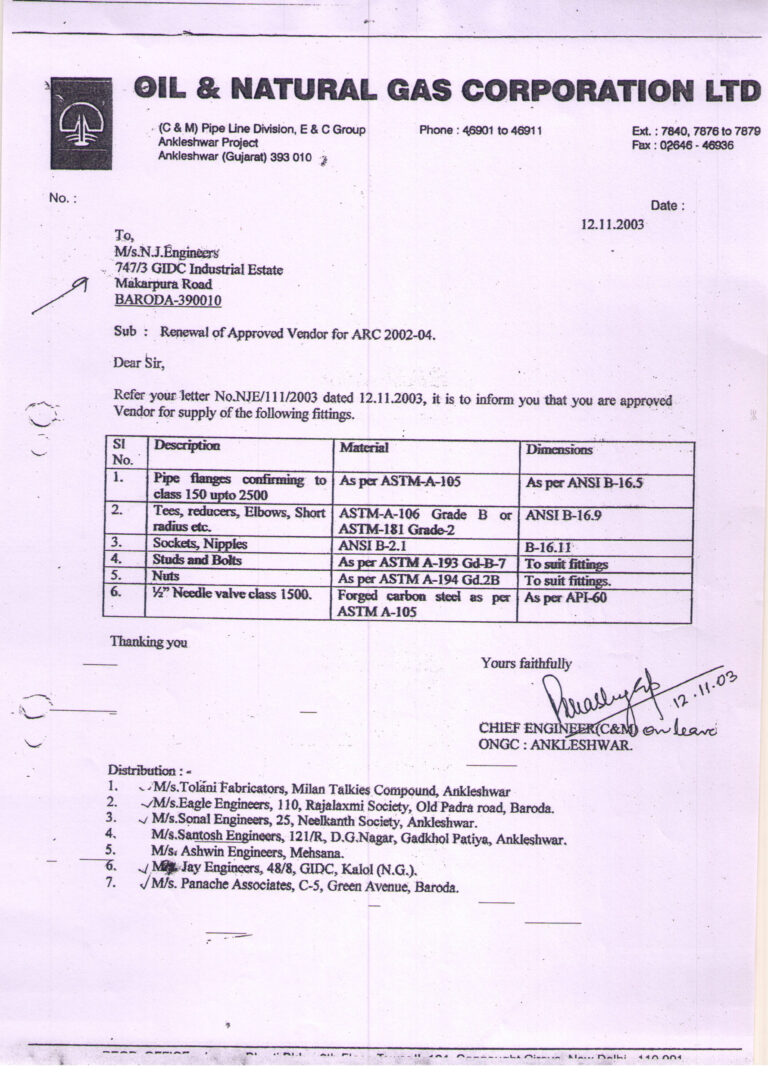

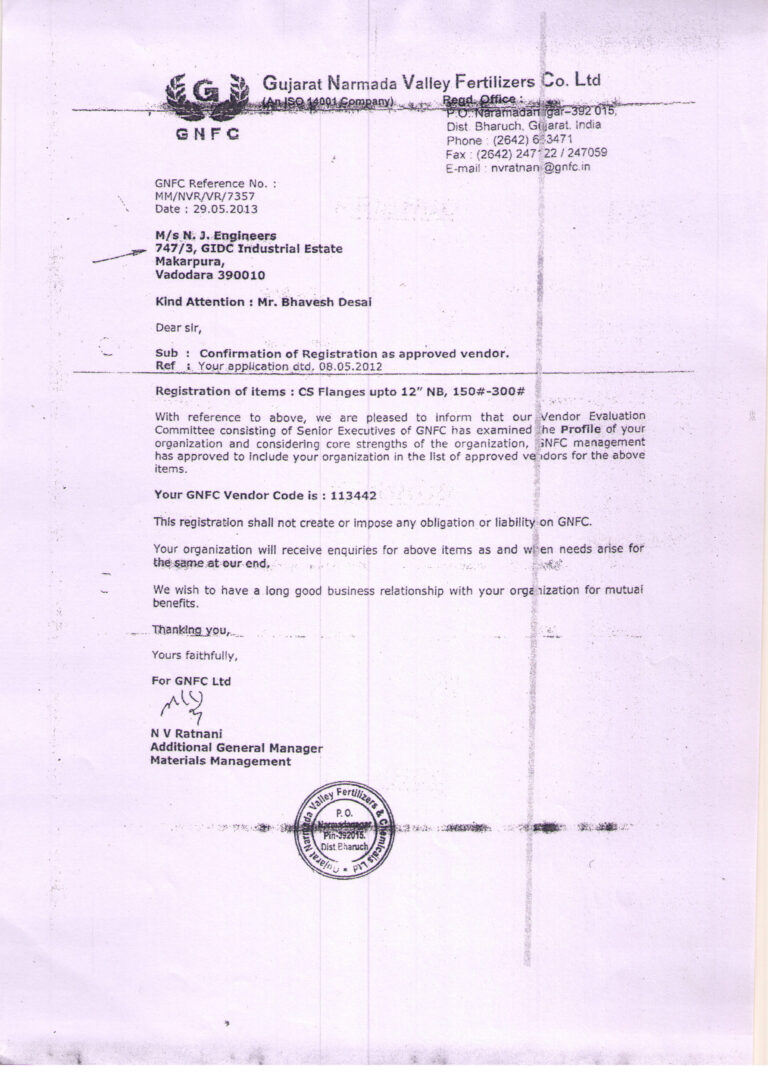

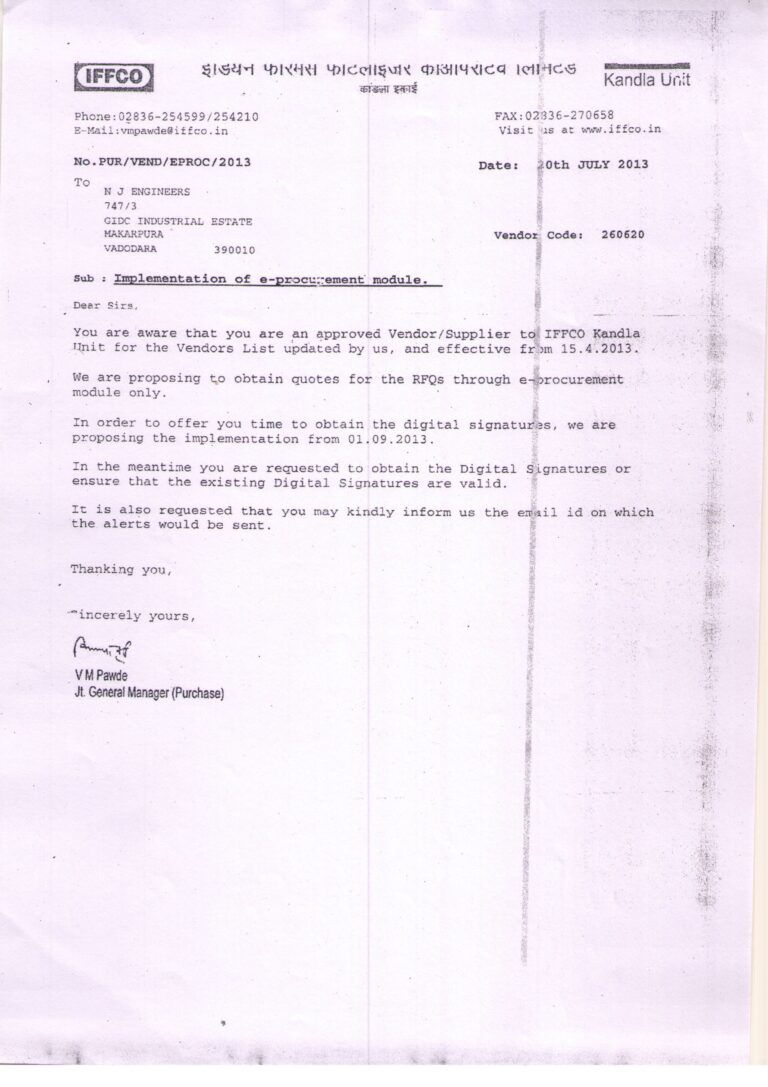

N J CERTIFICATES & ACHIEVEMENTS

We will keep you up to date with all of the latest architecture & construction news

What’s Next For Contech & Construction?

Building The Future Through Architecture

Is There Still A Market For Value-Add Construction?

What’s Next For Contech & Construction?

Building The Future Through Architecture